About us

Welcome!

Ever since our company’s founding in 1968, we at Gotō Welding in Tsubamesanjo in Niigata prefecture, a major industrial area for metal processing, have been striving to manufacturing the finest metal pipes.

Gotō Welding Co., Ltd. is a pioneer in pipe manufacturing, constantly looking to improve processing technologies required for the pipe manufacturing process such as winding, welding, and laser in order to respond to the demands of the market as it changes with the times.

Gotō Welding Co., Ltd. is a pioneer in pipe manufacturing, constantly looking to improve processing technologies required for the pipe manufacturing process such as winding, welding, and laser in order to respond to the demands of the market as it changes with the times.

Enriching lives with technology. At Gotō Welding, that’s our job.

Gotō Welding is based around the principle of promoting technology for the betterment of the world and the enrichment of human lives.

As this principle implies, we have always been a company that aims higher, never satisfied with the status quo, and is always looking to introduce new opportunities and joint development in the pursuit of higher quality and better efficiency.

We can’t be afraid of change. That is why we are committed to continuing our approach to business into the next generation through the active incorporation of useful products.

As this principle implies, we have always been a company that aims higher, never satisfied with the status quo, and is always looking to introduce new opportunities and joint development in the pursuit of higher quality and better efficiency.

We can’t be afraid of change. That is why we are committed to continuing our approach to business into the next generation through the active incorporation of useful products.

Gotō Welding Co., Ltd.

Representative Director Hideki Gotō

Representative Director Hideki Gotō

Company Strengths

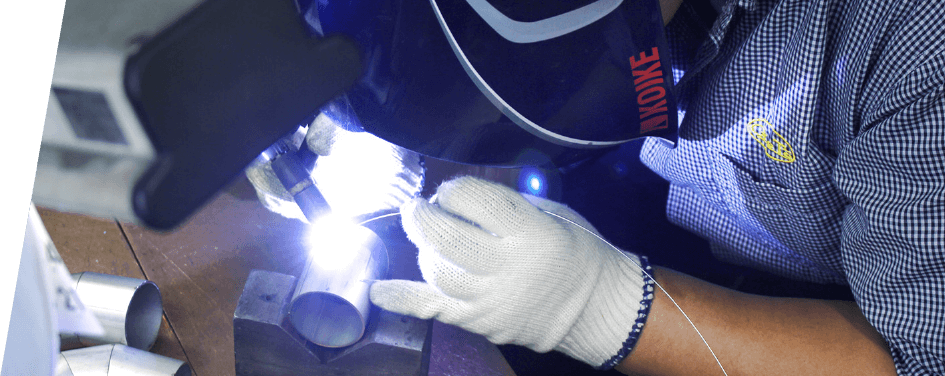

We respond to requests for pipe manufacturing through various processes such as winding and welding.

At our location in the metal processing town of Tsubamesanjo in Niigata prefecture, we use technologies such as winding, welding, pressing and spinning to manufacture pipes of various sizes.

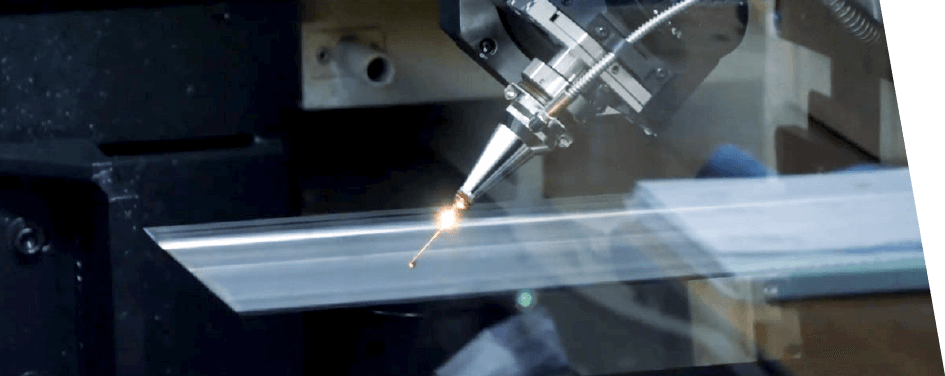

Using winding, spinning and 3D laser processing suited to the metal, we can meet the demand for high-quality, low-cost pipe products.

Using winding, spinning and 3D laser processing suited to the metal, we can meet the demand for high-quality, low-cost pipe products.

Skilled Craftsmanship x Spirit of Challenge

Alongside continuing our tradition of pipe manufacturing, we are always actively developing our own products, introducing the latest equipment, and pursuing new challenges.

We are investing in laser processing machines and roll machines to make the most of our craftsmanship through the latest processing technology in order to improve the efficiency of manufacturing pipe products.

We are investing in laser processing machines and roll machines to make the most of our craftsmanship through the latest processing technology in order to improve the efficiency of manufacturing pipe products.

TSO certification. Quality recognized by Tsubame, a city of craftsmen.

We have received TSO(Tsubame Standard Organization) certification, the monitoring association in Tsubame, Niigata that specializes in quality control.

We know that customer satisfaction depends on us producing reliable quality.

We know that customer satisfaction depends on us producing reliable quality.

Company Initiatives

In December 2016, our company launched a product development project that utilizes our own technology. We will continue to utilize the pipe manufacturing technology we have developed to make every effort to deliver safe and reliable products that assist and enrich people’s lives.

nigiri sushi molding machine“Sushi Tongs”

Stage 1

The development goal here was to be able to make nigiri sushi without touching the rice, motivated by the desire to eat delicious authentic nigiri sushi at home. Four years after first conceiving the ideas, we have completed the creation of “Sushi Tongs” which allow you to include a moderate amount of air to make the ideal nigiri sushi.

Repeated Trial Process (6 trials)

Because we were not satisfied with the texture of the rice produced with early models due to over-compaction, we reexamined the design in order to reach the desired shape and texture. It took 6 trials to get things just right.

Our Goal: Touch of a True Craftsman

In the end, we used a structure that presses vertically to imitate the way that plump sushi rice contains air when shaped by a sushi chef’s hands.

This design avoids crushing the air out of the rice when it is shaped by hand, giving it a texture much closer to that of a true craftsman.

This design avoids crushing the air out of the rice when it is shaped by hand, giving it a texture much closer to that of a true craftsman.